Smart inspection is a critical application in today’s low-altitude economy, covering various scenarios such as electrical inspection, renewable energy power station patrols, forest fire monitoring, water channel and hydroelectric facility surveys, and traffic monitoring. Typically, an industrial-grade multirotor UAV equipped with an inspection payload is used to replace human in high-risk or complex tasks, improving operational efficiency and reducing missed detection rates.

Over the years, SIYI TECHNOLOGY has launched multiple inspection payloads designed for diverse applications, including multi-sensor optical payloads, compact dual-sensor optical systems, high-magnification zoom payloads, mini zoom cameras, and industrial-grade ruggedized gimbal cameras.

In July 2025, at the invitation of a partner, SIYI’s team collaborated with client technicians to conduct a practical drill using the ZT30 multi-sensor optical pod mounted on a smart inspection UAV for detailed power tower inspection.

Project Challenges Analysis

The inspection payload serves as the “eyes” of the UAV. It must be stable and clear, capturing details reliably from a safe distance. It also needs to accurately identify issues using multiple sensors, enhancing both efficiency and accuracy. Transmission tower environments involve complex electromagnetic conditions, demanding high stability, imaging and zoom capabilities, and environmental adaptability from the payload.

Challenge 1: Unclear Imaging — Inefficiency & Missed Detections

Insufficient resolution and zoom capability: Small defects (e.g., fine cracks, missing pins, corrosion spots) may not be clearly captured from a safe distance.

Blurring due to instability: Vibrations during hover or flight, wind disturbances, and limited gimbal response can cause blurring, especially at full zoom.

Challenge 2: Identifying Hidden Issues — IR Split-Screen Reduces Missed Detections

Some structural issues, such as abnormal heating in tension clamp lead plates, are not visible to the naked eye. An infrared sensor allows temperature-based anomaly detection, helping to prevent potential failures.

Challenge 3: Low Inspection Efficiency — Difficulty Filtering Valid Information Quickly

Inspection tasks are often large in scale and complexity. AI-enabled payloads can quickly identify high-frequency fault points (e.g., damaged insulators) and help operators filter information efficiently.

Challenge 4: Electromagnetic Interference — Operational Failure Risks

High-voltage transmission lines generate strong electromagnetic fields that may interfere with the payload’s electronics (e.g., gimbal control, image transmission, sensors), causing operational errors or even failures.

Equipment Used in the Drill

Inspection Payload: SIYI ZT30 Multi-Sensor Optical Pod

Lenses: Wide-angle, zoom, infrared, laser rangefinder

EO Resolution: 4K ultra-wide-angle

Zoom: 30x optical zoom, 180x hybrid zoom

IR Resolution: 640×512 pixels, supports split-screen EO/IR imaging, point/area/global temperature measurement

Weight: 854g

Operating Temperature: -10°C to 50°C

UAV Platform: Reebot Robotics UniDrone E900 Industrial-Grade Multirotor Drone

Ground Station: SIYI UniRC 7Pro High-Performance Handheld Ground Station

Software: UniGCS Ground Station Software

Smart route planning

Dual-channel low-latency HD video display

One-touch photo, video, gimbal control, and thermal imaging

Field Operation & ZT30 Performance

Step 1: System Check and Takeoff

The ZT30 was mounted on the UniDrone E900 using an anti-vibration quick-release mount. The team ensured sufficient battery levels, secured all components, and confirmed that the FPV and ZT30 lenses were clean and unobstructed. The UAV took off from an open area after frequency matching.

Step 2: HD Visible Light Inspection — Insulators, Counterweights, Vibration Dampers

The UAV flew at high altitude to inspect insulator integrity. Under high-magnification zoom, dirt accumulation and rusted counterweights were identified. Damaged insulators and displaced vibration dampers were also detected. Wide-angle scanning revealed a hanging phase sequence plate and a bird’s nest at the tower top.

The ZT30’s 30x optical zoom and 180x hybrid zoom capabilities, combined with 4K imaging, enabled clear observation of potential risks. The three-axis stabilized gimbal ensured sharp imaging even at full zoom, and unlimited yaw rotation allowed 360° coverage.

Step 3: Infrared Inspection — Split-Screen and Temperature Measurement

Using UniGCS’s split-screen EO/IR imaging with linked zoom, the team examined temperature conditions at key points on the tower. No abnormal heating was found in the tension clamp lead plates or tower structures.

The ZT30’s 640×512 IR sensor supports 6x zoom and three temperature measurement modes (point, area, global), enabling efficient detection of hotspots.

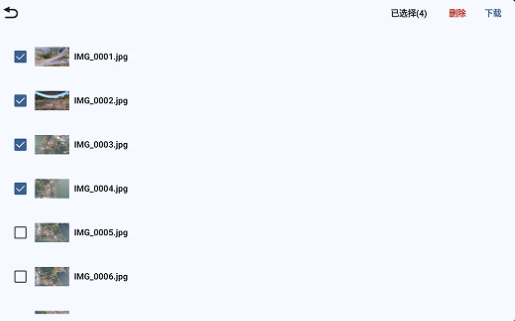

Step 4: Return and Data Archiving

The UAV returned safely, and EO/IR imagery was exported for analysis and historical comparison.

ZT30 Performance Against Project Challenges

Unclear Imaging: The 4K sensor and 30x optical zoom significantly improved detection accuracy, with minimal quality loss at high zoom. The stabilized gimbal ensured sharp imagery.

Hidden Issues: Split-screen EO/IR imaging with linked zoom allowed efficient temperature comparison and anomaly detection.

Low Efficiency: The ZT30 supports AI-based recognition of key components (e.g., insulators) via SIYI's AI Tracking Module II. Wide-angle and zoom modes can be quickly switched, with an average power consumption of 9W.

EM Interference: The ZT30 performed reliably with no interference-related issues such video flickering or signal loss.

Conclusion

This practical drill demonstrated the SIYI ZT30’s capabilities in detailed transmission tower inspection, including stable gimbal control, HD zoom, split-screen EO/IR imaging, and temperature measurement — significantly improving efficiency and reducing missed detections.

SIYI TECHNOLOGY remains committed to R&D and innovation in core components for intelligent robotics, delivering high-performance product-level solutions that enable UAV manufacturers and distributors to respond quickly to market needs and achieve higher integration and innovation.

Scan to follow the official account